Hello ,

Munavver here from LeanEdge360 . Today let me share you something on the cost of Quality that organisations incur when they produce or serve any solutions to their customers. Even though , the biggest costs of poor quality such as “loss of reputation” or “ loss of potential future sales “ cannot be really measured , there are many indicators that will give you some idea about how it has affected your business. Today I will give you some introduction on various types of costs associated with quality.

Introduction:

Maintaining high quality standards comes with a price tag – the Cost of Quality (COQ). The concept of COQ encompasses both the tangible and intangible expenses associated with achieving and maintaining quality in products or services. By understanding the various components of the Cost of Quality, businesses can make informed decisions that not only enhance product or service quality but also contribute to overall efficiency and profitability.

Components of the Cost of Quality (COQ) :

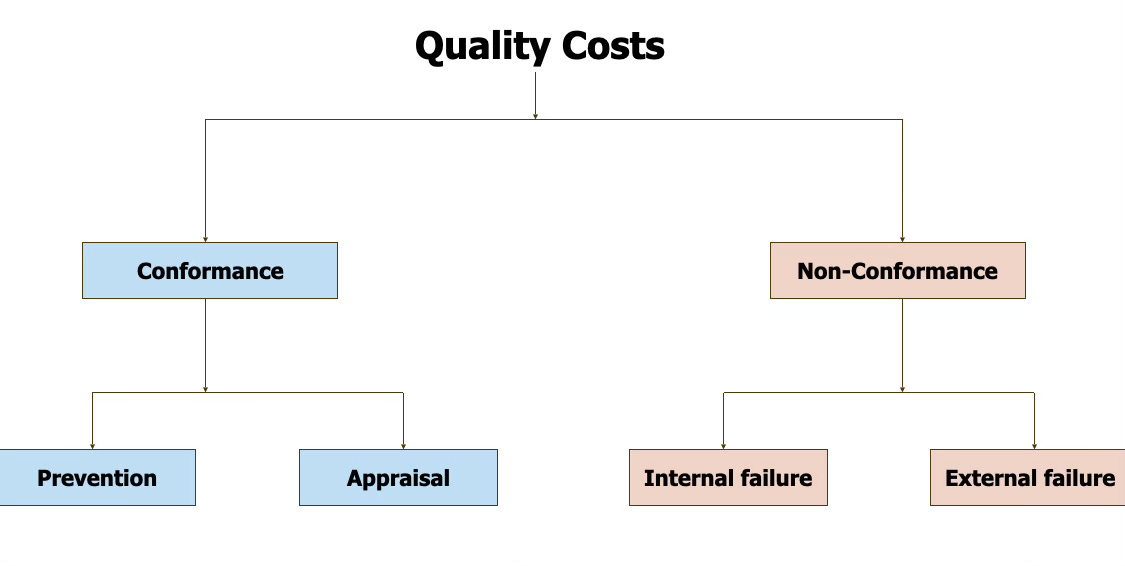

There are two categories to the components of the COQ .

The cost of conformance which includes the prevention and appraisal costs and the cost of non conformance which includes the internal and external failure costs. While the former are the costs associated with producing and ensuring quality , the later are the costs associated with repairing and handling the problems that occcured due to not meeting the minimum standards of the quality and expectations of the customers.

Hence , you can classify the total costs in to the 4 types of costs as shown in the figure

Prevention Costs: Prevention costs are incurred to avoid defects before they occur. These proactive measures include employee training, process improvement initiatives, quality planning, and the implementation of robust quality management systems. Investing in prevention helps identify potential issues early in the production process, reducing the likelihood of defects and rework.

Appraisal Costs: Appraisal costs are associated with the assessment of products and services to ensure they meet predetermined quality standards. This includes inspection, testing, and quality audits. While prevention costs focus on stopping defects before they happen, appraisal costs involve identifying and rectifying defects during or after production. Though necessary, excessive appraisal costs may indicate underlying issues in the production process.

Internal Failure Costs: Internal failure costs arise when defects are detected before products or services reach the customer. These costs encompass rework, scrap, and additional resources required to rectify the problem. Reducing internal failure costs involves identifying and resolving issues within the organization before they lead to customer dissatisfaction.

External Failure Costs: External failure costs are incurred when defects are identified after products or services have reached the customer. These costs include warranty claims, product recalls, customer returns, and damage control. Not only do external failure costs impact a company's bottom line, but they can also harm its reputation and customer trust. Investing in prevention and early detection helps minimize these costs and build long-term customer relationships.

Balancing the Cost of Quality:

The goal for businesses is to find the optimal balance between prevention, appraisal, and failure costs. While it may be tempting to cut corners and reduce costs in the short term, the long-term consequences of poor quality can be far more damaging. Implementing efficient quality management systems, fostering a culture of continuous improvement, and investing in employee training contribute to a sustainable approach to managing the Cost of Quality.

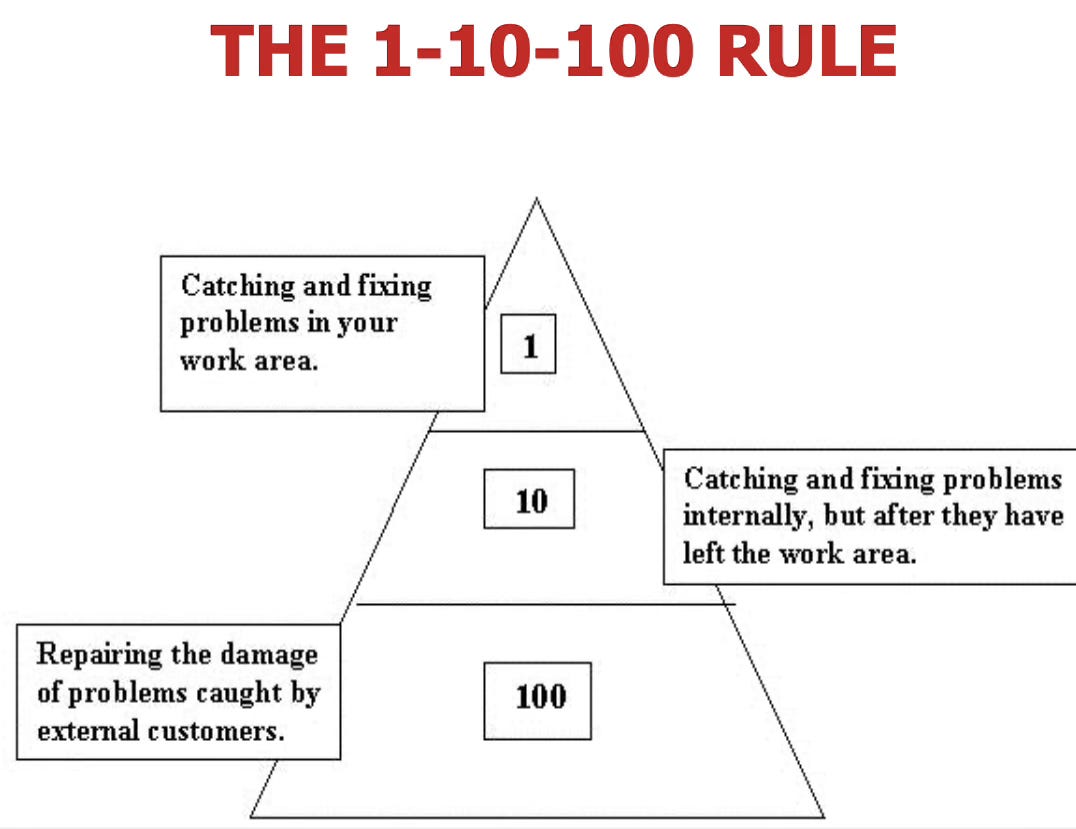

To understand better , Here is an illustration of 1-10-100 rule, which says that the cost of external failure due to poor quality will be always 10 times more than the cost of internal failure and will be 100 times more than the prevention and appraisal costs. Therefore , without doubt , any business regardless of what industry they are in , should put their focus on preventing the costs associated with the non conformance or failure of their products or service.

Benefits of Managing the Cost of Quality:

Enhanced Customer Satisfaction: High-quality products or services lead to increased customer satisfaction and loyalty. Satisfied customers are more likely to become repeat customers and advocates for the brand.

Operational Efficiency: By investing in prevention and process improvements, businesses can streamline their operations, reduce waste, and increase overall efficiency. This not only reduces costs but also improves the organization's competitiveness.

Brand Reputation: A commitment to quality can build a positive brand image, fostering trust among customers. A strong reputation for delivering reliable products or services can be a powerful differentiator in the market.

Cost Savings in the Long Run: While the upfront investment in prevention may seem high, the long-term cost savings from reduced defects, rework, and customer complaints outweigh these initial expenses.

Conclusion:

Understanding and managing the Cost of Quality is crucial for businesses aiming for sustained success in today's competitive markets. By strategically investing in prevention, appraisal, and addressing internal and external failure costs, organizations can create a culture of quality that not only meets customer expectations but also contributes to operational excellence and long-term profitability. In the end, the true cost of quality is not the expense incurred but the value gained in customer satisfaction, operational efficiency, and a positive brand reputation.

Are you calculating the four components of costs of quality in your organisation ? If yes , tell me how you do it and what has changes after that !

Thanks for reading . If you wish to have more information on the articles , WhatsApp me .

Best,

Munavver Fairooze Follow me on Linkedin here

This newsletter is powered by LeanEdge360 , A TPS way Lean Management consulting firm based in Dubai, UAE . We help our clients to

Improve profitability by improving productivity

Improve sustainability by improving employee engagement and quality

Check out our Linkedin page and our Website here !