Hello.

Munavver here.

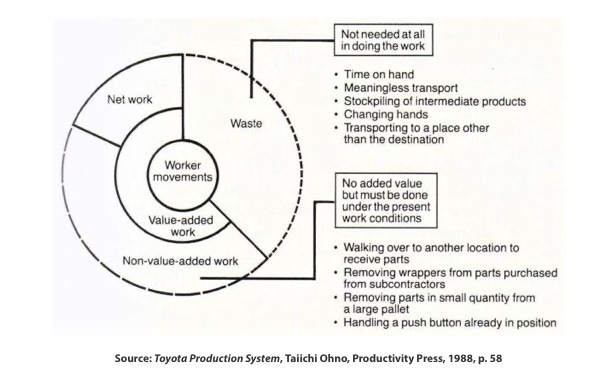

Today, let’s talk about the basics. What are the Value-Adding and non-value-adding activities in an organization?

Value-Adding Activities:

Actions or processes that directly contribute to meeting customer needs or enhancing a product or service.

In short, these are the activities that customers are ready to pay for.

They add value from the customer's perspective and are essential for the creation of the final product. Identifying and optimizing value-added activities is a central principle of Lean thinking.

Examples of Value-Adding Activities:

Manufacturing: In a manufacturing context, activities like cutting, welding, assembling, and painting are considered value-added because they directly transform raw materials into finished products that customers are willing to pay for.

Design and Engineering: The design and engineering of a product to meet customer requirements are value-adding activities as they directly contribute to creating a product that satisfies customer needs.

Customer Service: In service industries, activities like attending to the customers to provide information about products or services they offer, answering questions, transferring the products to their ownership, etc can be considered value-added activities.

Non-Value-Adding Activities:

Often referred to as "waste," are actions or processes that do not directly contribute to meeting customer needs or enhancing a product or service. These are the activities that customers are not ready to pay for.

These activities consume resources, time, and money without creating value for the customer. Identifying and eliminating non-value-adding activities is a key principle of Lean Management.

There are many activities that may be “necessary” even if they do not add value but without them, it would be impossible to perform the value-added activities at the current conditions. An example of this is

“Material/product/part movement from one location to another location to perform additional tasks that add value.

Here are more examples of Non-Value-Adding Activities:

Packaging: Packaging a product to protect it during shipping and enhance its presentation may seem to be value-adding, but it is considered another “necessary” non-value-added activity as it does not transfer the product more useful.

Quality Control: Inspecting and testing products to ensure they meet quality standards is also another non-value-added activity because customers wouldn’t have to pay for “making sure” that only good products are delivered to customers.

Defects and Rework: Any activity required to correct defects or rework products represents non-value-adding work. It consumes resources and time without adding value to the customer.

Excessive Paperwork: If administrative tasks and paperwork do not directly contribute to customer satisfaction or regulatory compliance, they are considered non-value-adding activities.

In Lean thinking, the goal is to minimize or eliminate non-value-adding activities while maximizing value-adding activities to improve efficiency, reduce costs, and enhance customer satisfaction.

It is also interesting that given the definition of value-adding and non-value-adding activities in an organization, the amount of time that’s spent on creating value in an average manufacturing organization is much less ( less than 1-5 %)!

This indicates a huge potential for improving the processes to eliminate the waste majority of non-value-added activities. Here is a picture from Taichi Ohno’s ( one of the founding fathers of TPS ) book for better understanding.

Ready to start your lean journey? Get in touch today.

Best,

Munavver Fairooze (Connect with me on Linkedin)

What’s the number one problem that you need to solve to increase revenue at your company? Take this survey